Technical Research of Galvo Scanner in Imaging Laser Rader

Laser radar is the product of radar technology and laser technology. Laser radar emits laser to irradiate the target and receives its echo. In this way, the information of the distance, position, radial velocity, the target surface reflectance from the target irradiate to the launching point can be obtained. According to obtaining the types of target information, laser radar can be divided into laser range radar, laser Doppler radar, laser measuring angle tracking radar and imaging laser radar etc. Imaging laser radar is an active sensor technology. Compared with the passive imaging system of the visible and infrared light, imaging laser radar can quickly extract the 3D spatial coordinates of the object, obtaining the position, distance and shape of the target. Imaging laser radar has a broad application prospects in military. It can be equipped on mobile platform of land, sea and air, executing mission like target recognition, imaging guidance, battlefield reconnaissance etc. According to the different imaging way, imaging laser radar can be divided into non-scanning imaging laser radar and scanning imaging laser radar.

The main scanning ways of imaging laser radar are mechanical scanning, sound and light scanning, electro-optical scanning and binary optical scanning. Mechanical scanning means that mirrors are rotated by motor drive, which use the principle of geometrical optics to achieve a beam deflection. Mechanical scanning has a large lens with high scanning rate. And different scanning results can get different scanning images. Scanning imaging laser radar is widely used in scanning mode. Scanning imaging laser radar is oringal from a single point laser radar. It changes the beaming pointing at the target surface by planar laser galvo scanner. It measures the distance by pulsed laser measurement to obtain the 3D imaging of the target area. The key technology of scanning imaging laser radar is high power and high quality beam laser, high performance galvo scanner, high sensitivity receiver and image processing and object recognition algorithms.

Two-dimensional scanning galvanometer with high performance is the key technology and hardware in scanning imaging laser radar. The main role is that letting the emitted laser beam shifting regularly, and then scanning the target surface. The requirements of the scanning imaging laser radar to two-dimensional laser galvo scanner include: large field of scanning, high scanning rate, low energy attenuation, uniform scanning point distribution and synchronization acceptance transmit etc. Scanning galvanometer tilt angle is the important parameter of imaging laser radar, which reflects the size of the laser radar. The scanning rate determines the imaging laser radar to obtain a three-dimensional image of the frame rate. The higher scanning rate, the better the image will be in real time, which is especially important in military applications. 2D laser scanning galvanometer need to simultaneously finish the optical axis deflection of the transmission optical system and reception optical system to achieve synchronous transmission and reception and distance measurement.

To obtain spatial distribution of the lattice with the scanning imaging laser radar, the method that generally used is the equal time intervals emitting laser pulses and the mechanical scanner mirror rotating to linear law. As for the scanning galvanometer, when the direct of the axis perpendicular to the incident light and the mirror in accordance with the law of the triangular wave, the incident light perpendicular the axis of rotation in the case of the mirror with small displacement. The distribution of the reflected light of the scanning spot is uniform. In the two-dimensional scanning, the inherent characteristics of the reflected beam can’t simultaneously satisfy the conditions of the two scanners uniform scanning, so the scanned images will distort.

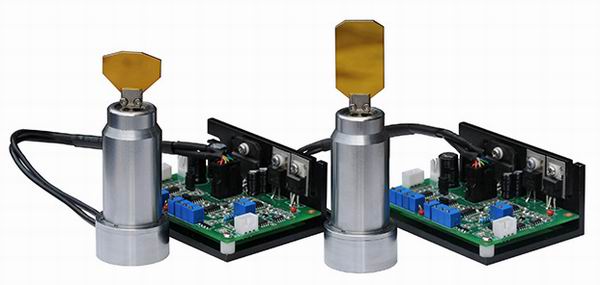

Galvanometer scanner is composed of scanning mirror, a swing mirror, position sensor, driver circuit and the servo controller etc. It is a high precision position servo control system. Currently, the scanner used for scanning imaging laser radar is galvanometer scanner, the appearance shown in Figure 1.1.

Figure 1.1 Galvanometer Scanner

Galvanometer scanner is the closed-loop feedback system, has the characteristic of big angle, high accuracy, high speed, small volume etc. Sino-Galvo developed the most advanced various models galvanometer scanning system after many years research. JD1403 and SG7210 have the characteristic of high speed and accuracy, the detailed specification as below:

Parameter scanning motor

Working Temperature | 0-45°C |

Linearity | 99.9% |

Setting Time | ≤0.3ms |

Scale Drift | 40PPM/°C |

Zero Drift | <15μRad./°C |

Long-term Drift Over 8 Hours | <0.5mRad |

RMS Current | 2.0A |

Peak Current | 15A(Max) |

Maximum Scan Angle | ±15° |

Storage Temperature | -10 to +60°C |

Resolution | 12μrad |

Repeatability | 8μrad |

Input Aperture | 10mm |

Beam Displacement | 13.4mm |

Motor Weight | 120g |

Frequency | ≤1000Hz |

The parameters of servo drive plate

Input Voltage MAX.RMS | ±15VDC |

Interface Signals Digital | XY2-100 |

Position Signal Input Resistance | 1K±1% Ω |

Position Signal Input Scale Factor | 0.33V/° |

Position Signal Output Scale Factor | 0.33V/° |

Working Temperature | 0-45°C |

Dimension(L×W×H) | 75×45×30mm |